Grand Seiko timepieces run the gamut of case metals. Today, we’re going to take a closer look at some of the different materials used to make Grand Seiko cases, including stainless steel, two titanium alloys – High-Intensity Titanium and Brilliant Hard Titanium, gold, and platinum.

The vast majority of Grand Seiko watches are made of 316L stainless steel, which is generally regarded as the industry standard. 316L is known for its low carbon content (in fact, that’s what the “L” denotes), anti-magnetic properties, and its excellent resistance against corrosion. What differentiates 316L from 304 stainless steel, which is the most common stainless steel alloy in general use, is the addition of molybdenum, a silvery-white metal that increases the alloy’s resistance against corrosion and pitting, and also increases its strength at higher temperatures. The latter is especially important during the manufacturing process.

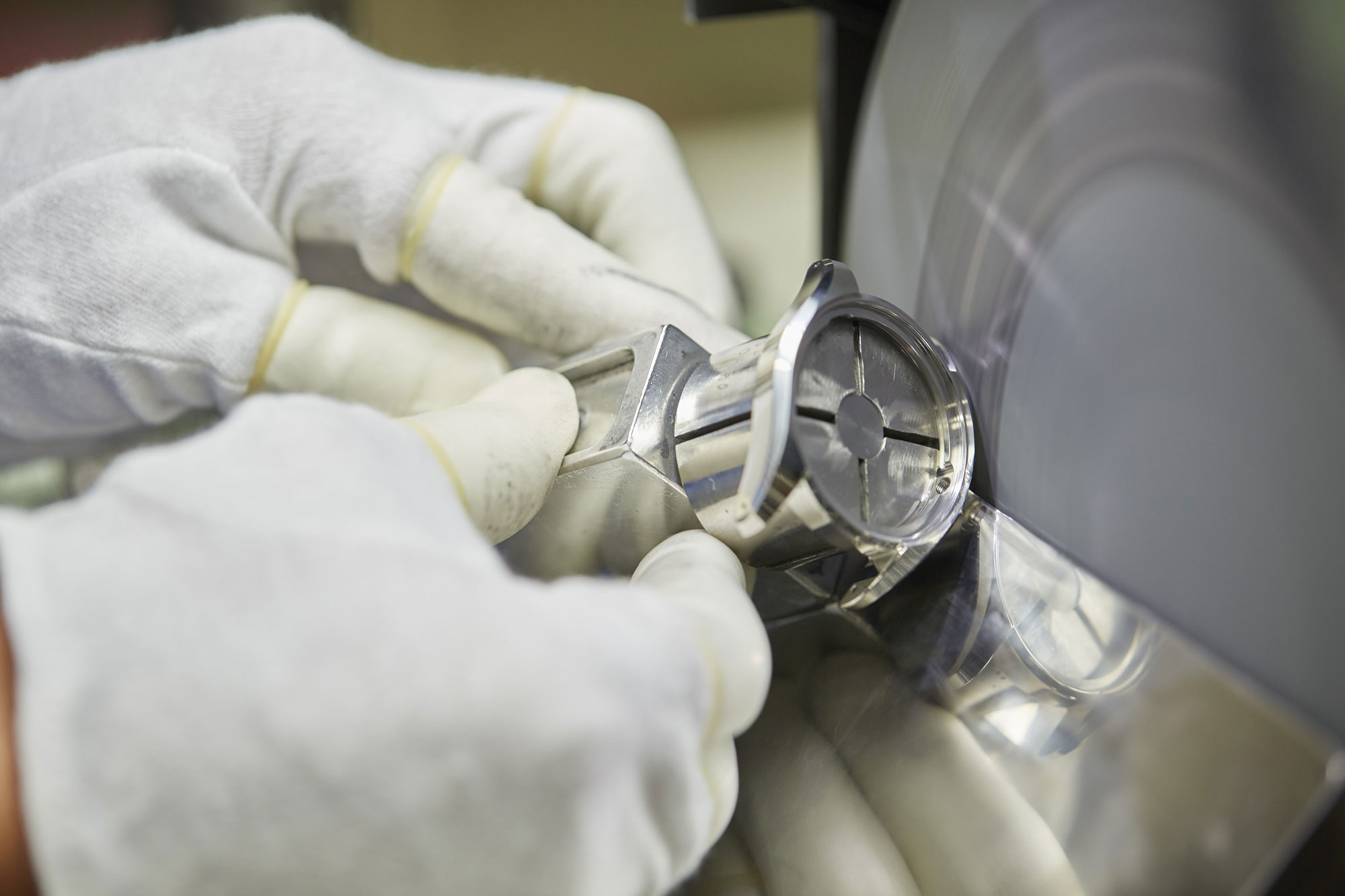

Grand Seiko’s steel cases are finished to an incredibly high standard. The brand is known for its distinct Zaratsu polishing, which creates Grand Seiko’s iconic distortion-free cases. Zaratsu is a labor-intensive process that requires great skill and experience from those entrusted with the work, but the results speak for themselves. Many cases also feature hairline finishing, and the contrast between the two types of finishes gives Grand Seiko watches their inimitable look.

Stainless steel is not a lightweight metal, so a stainless steel watch, especially on bracelet, comes with some perceptible heft on the wrist. Many enjoy this feeling, though as we’ll cover below, some people may prefer the lighter weight of titanium.

Titanium is generally prized for its superior corrosion resistance, lightness, and hypo-allergenicity, an important factor for those who cannot wear stainless steel due to a nickel allergy. High-Intensity Titanium is the name of an alloy Grand Seiko uses on the vast majority of its titanium-cased watches. Models include the SBGA211 “Snowflake”; SBGA413 and SBGA415 from the Japan Seasons Collection; and SLGA001, Grand Seiko’s latest professional diver powered by caliber 9RA5. There’s also Brilliant Hard Titanium, another alloy from Grand Seiko. It has only been used twice by the brand – the first time with reference SBGR305, one of the inaugural watches launched by an independent Grand Seiko in 2017, and the second time with SBGW259, a 2020 release inspired by the first Grand Seiko watch from 1960.

Often, titanium watches have a muted, gray look. This is not so with Grand Seiko’s High-Intensity Titanium, and especially not with Brilliant Hard Titanium. Though it is a bit grayer in appearance than stainless steel, High-Intensity Titanium has a much brighter finish than most other grades of titanium used in the industry, and Brilliant Hard titanium appears even more brilliant (hence the name) than watchmaking stainless steel. Both alloys can be finished to an incredibly high standard via Grand Seiko’s Zaratsu technique, which had to be adapted from stainless steel to work with the distinct properties of titanium.

Titanium watches are significantly lighter than their stainless steel counterparts. As a point of comparison, ref. SBGA229, rendered in stainless steel, weighs 201 grams. Ref. SBGA231, which features largely the same design but in titanium, weighs 137 grams. Altogether, that’s a decrease of about 32%, which is noticeable on the wrist. If you are not used to wearing titanium watches, the lightness may feel a bit unusual at first, but it’s incredibly comfortable.

The hardness of High-Intensity Titanium is much higher than that of pure titanium, and Brilliant Hard Titanium is around four times harder than stainless steel. Because Grand Seiko’s titanium is so hard wearing, there is no need for the use of any surface coatings, which can diminish the brilliance of the metal. Using a coating can also limit one’s ability to refinish their watch in the future.

Generally, Grand Seiko’s titanium watches are priced higher than comparable stainless steel models. This is largely because the raw material is more expensive to produce, and working with the metal is more labor intensive.

Grand Seiko employs the use of 18k yellow, rose, and white gold across a number of different watches and case designs in Grand Seiko’s catalog, from the classically styled SBGW258 to the geometrically complex SLGH002. Platinum 950 is generally reserved for limited edition models and references produced by the Micro Artist Studio, among them SBGD201 and SBGZ003.

Most of Grand Seiko’s watches in platinum and gold are cold forged. Today’s cold forging technique creates a precise case shape via a mold and extreme pressure, and in the process the metal is annealed, resulting in a harder case that can better tolerate re-polishing in the future.

In some instances, when a case is cold forged, it is intentionally made slightly larger than what the finished product would be by fractions of a millimeter. This is done so the case can undergo a light milling process that brings it closer to its final shape before finishing.

Like Grand Seiko’s stainless steel and titanium pieces, watches rendered in gold and platinum are also finished via the Zaratsu process. As was done with titanium, Grand Seiko had to adapt Zaratsu to work with the particular qualities of each material.

Gold is a soft metal, so it is difficult to produce sharp edges on an 18K gold case. To deal with this, the polisher has to carefully adjust the rotation speed and force of the polishing disc in just the right manner to achieve the desired sharpness without damaging the case. Similarly, Grand Seiko had to rethink their approach entirely with platinum. Because platinum is a soft and sticky metal, relative to steel at least, special attention had to be paid to the type of abrasive used. If it is too course, the abrasive may stick to the case, creating small holes in its surface. Over the course of a year, a multi-step finishing process was developed to prevent this from happening, making platinum one of the hardest case materials to work with in Grand Seiko’s catalog.